About the Project

The client sought to ensure full control over production quality — a tamper-proof Quality Gate that would completely prevent the release of defective parts and guarantee full consistency throughout the manufacturing process.

About the Project

The client sought to ensure full control over production quality — a tamper-proof Quality Gate that would completely prevent the release of defective parts and guarantee full consistency throughout the manufacturing process.

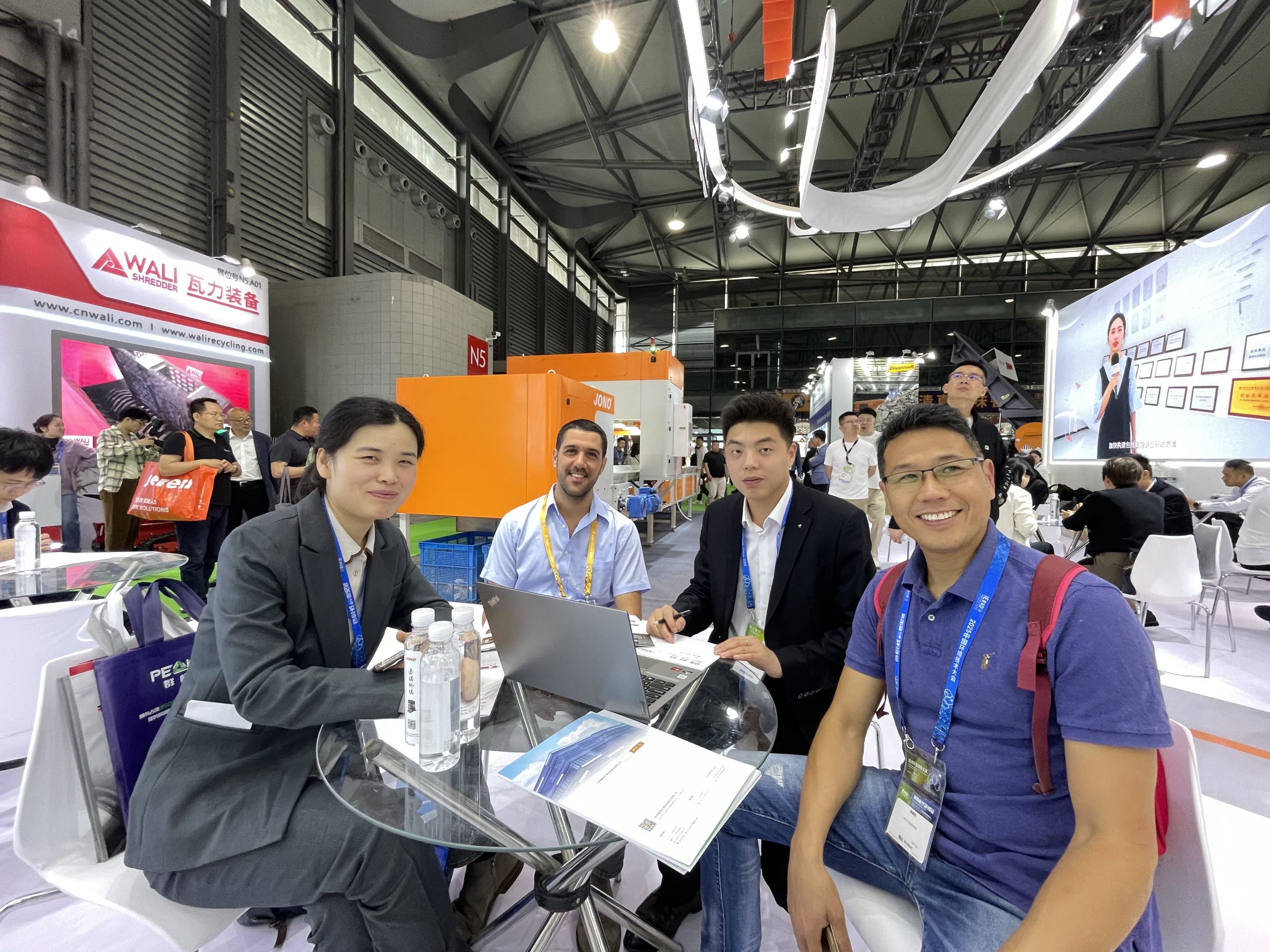

Sinergy managed the project end-to-end – from identifying and integrating two expert partners from China: one specializing in hardware and the other in software; all the way to defining the technical interfaces, managing ongoing communication, conducting design reviews, overseeing the integration process, and supporting on-site commissioning until final delivery.

The system developed is an interactive, locked visual inspection station designed to identify and approve only defect-free parts.

Each part is locked in place, photographed, and its image is compared to a reference model.

The solution is modular and scalable: the number of cameras and optical configurations can be adjusted to match the geometry and tolerances of each part, providing maximum flexibility for the client.

As part of the payment terms, we secured an agreement stipulating that 40% of the machine’s cost would be paid only after the client approved its performance at the factory in Israel (!)

The client’s engineers maintained continuous communication with the manufacturer in China.

Remote test runs were conducted, and the concept was developed and refined throughout the process.

From the negotiation stage and technical consulting to production quality control and shipment to Israel.

An equivalent solution was quoted by a leading Israeli provider at more than twice the cost!

Sinergy is here to connect you with the most reliable and high-quality suppliers in China — with professionalism, accountability, and zero risk.

We’re here to guide you every step of the way.